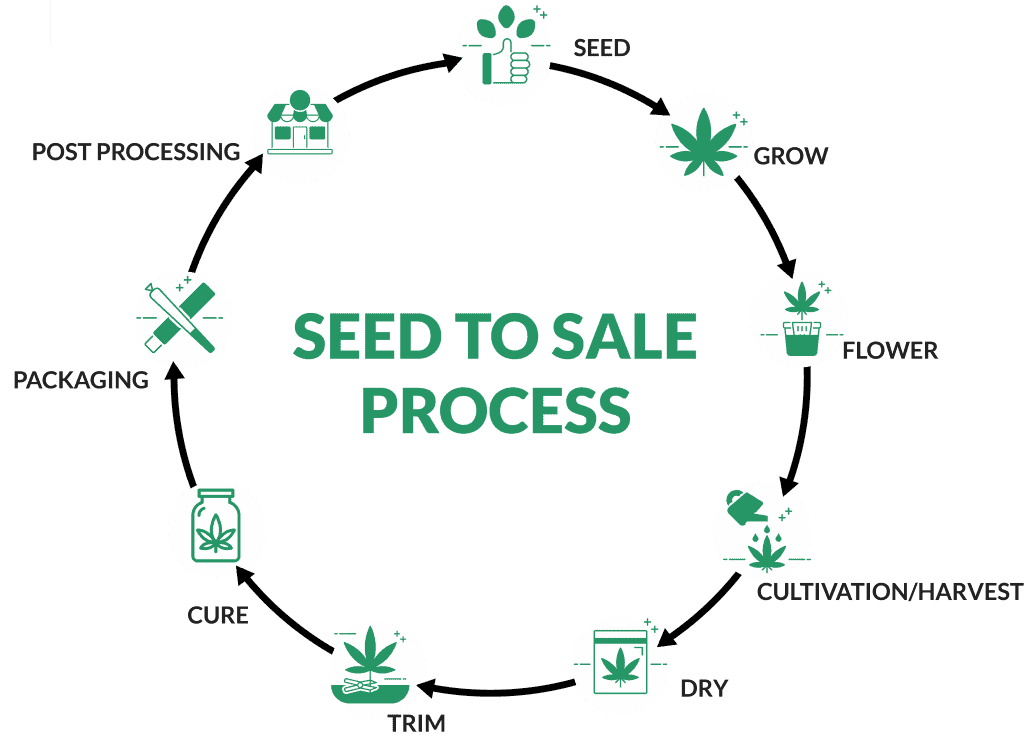

When we talk about seed to sale, we are referring to the entire production chain of a cannabis company. They start by planting the seeds on their farms, they grow the plants, harvest those plants, process everything, and then package it before it goes to the customer. Some cannabis companies handle the entire inventory management process from start to finish or as we say, seed to sale. When doing this, extensive tracking systems are required due to different legislation and regulatory compliance enforcement.

How Does Seed to Sale Work?

The seed-to-sale process is a term used to describe all of the steps in growing and distributing cannabis from sprouting seeds to selling products to consumers.

The seed-to-sale process is a term used to describe all of the steps in growing and distributing cannabis from sprouting seeds to selling products to consumers.

Seed-to-Sale Process:

Seeding

Whether it’s from a seed or a clone, growing cannabis comes with a variety of advantages and disadvantages. Clones are consistent and the gender is always known, given a similar environment to their parent strain they will produce the same amount of product. Seeded plants maintain their tap roots, allowing them to grow stronger and faster but have a greater potential to grow into males, destroying an entire operation overnight.

Growing

An effective and methodical grow stage is critical to any successful cannabis operation. Maintaining proper nutrients, lighting, oxygen levels, CO2 levels, and water levels through the vegetation stage along with battling pest and overgrowth can truly mean the difference. Without proper upkeep, newly developed plants can quickly die, while older plant are still susceptible to these same challenges, they’re far more resilient to stressors. Careful maintenance can ensure plants stay stress free, allowing them to grow to their maximum potential and prevent any chance of a sex change.

Flowering

The flowering stage of a cannabis plant can easily be the most hectic, it’s important that the plants are carefully transitioned into their new nutrient set overtime. A single overnight switch has the potential to jeopardize all of the hard work that’s been poured into these plants over the last few months. Ensure the plants are properly supported as they stretch and that they are receiving appropriate lighting to maximize growth. After a few weeks of stretching the plants will have fully transitioned into budding, becoming thicker and significantly taller.

Harvesting/Cultivation

In the closing weeks before harvest the buds should be nearly completed, milky white trichomes, a pungent odor, and darkening/amber hairs are great signs that all of your hard work is nearly ready to pay off. Consider flushing the plants of all of the added nutrients in the final two weeks to avoid any harsh chemical tastes, giving your plants flavors an opportunity to shine. It’s generally recommended that you keep you plants in a dark room just prior to harvest to protect your trichomes THC.

Drying

Drying can make or break your harvest, which is why precision and patience are key in this stage. A solid week of drying in a pitch-black room with effective circulation and humidity control are always components of best practices. When the bud itself is dry and the stems can bend or pop without breaking, that’s why you know it’s time to move onto the next step. Consider Bud Washing if you’ve been using pesticides or are growing outdoor to clear off any unwanted flavors.

Trim

Everyone’s favorite chore, trimming your plants can be a tedious and rewarding process. Whether it’s a dry trim or a wet trim, this processing stage will set the visual tone of your plants. Wet trimming is done directly after harvest before the drying stage, this can allow for an easier time trimming as the sugar leaves have yet to curl back into the plant. Wet trimmed plants generally dry faster and with the

Curing

From the moment you harvest your plants, they begin to break down. A proper cure can prevent cannabinoids and terpenes from breaking down into less favorable compounds. Immediately after trimming the buds should be placed into sealed containers or bag and kept in a cool dark room. Burping containers while monitoring humidity are essential practices to preventing mold and preserving taste. Humidity packs are available from a wide variety of vendors that will allow control over the bud’s environment. While burping containers, be aware of the smell within the first few days, this

Packaging

Deciding how to package your product ultimately decides whether the product will leave the shelf or not. The packaging step includes sorting out the flowers and deciding which are suitable enough to be sold as bud on the shelf or sent for post processing such as extraction or joint rolling.

Post Processing

All those trimmings and buds that did not make it to the shelf should not be thrown away. They can become other useful products that can still be sold to consumers. Trimmings can be filtered with ice cold water to create bubble hash. Leftover buds can be used to make pre-rolled joints or pressed to create waxes, shatter, etc.